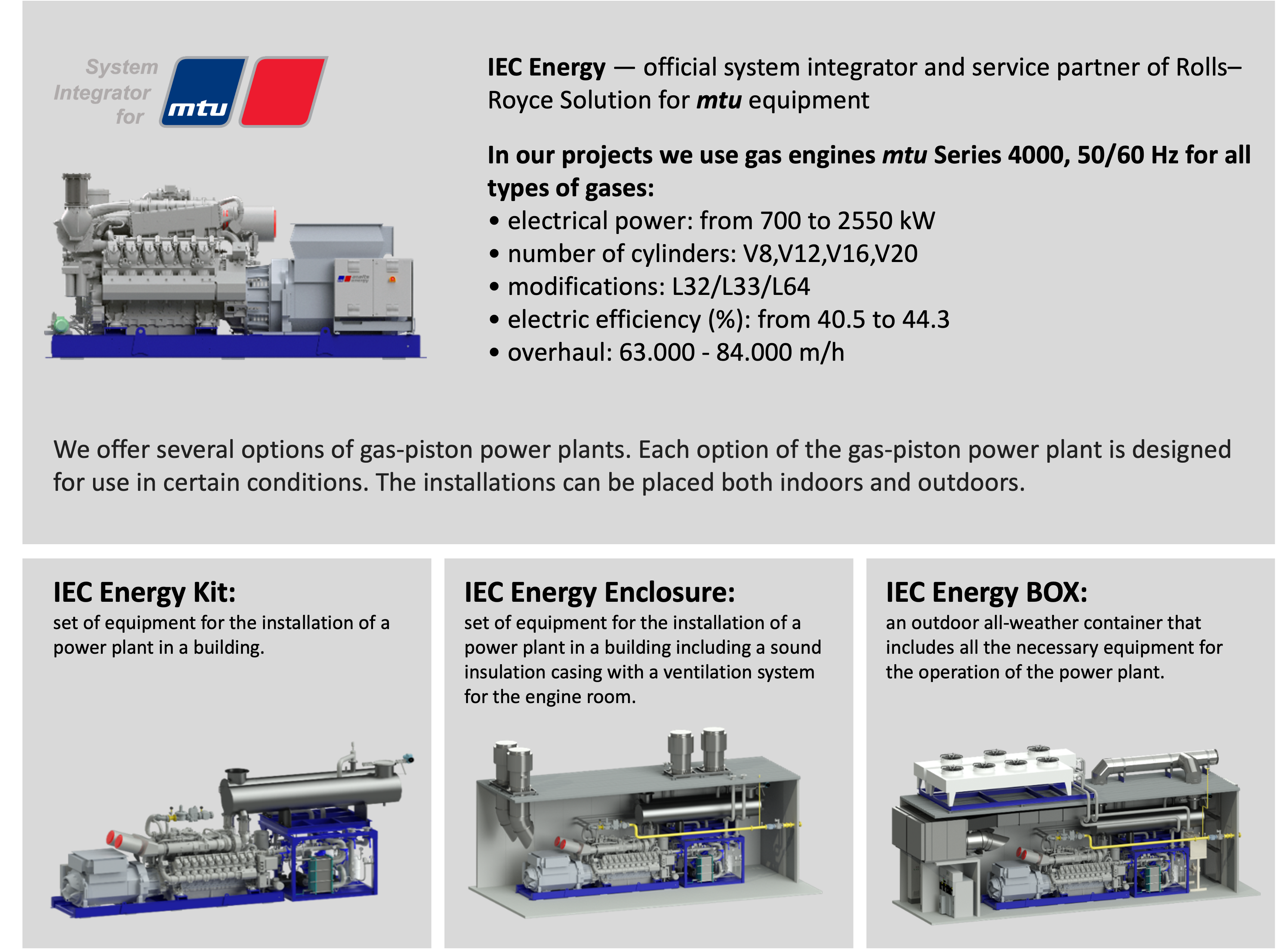

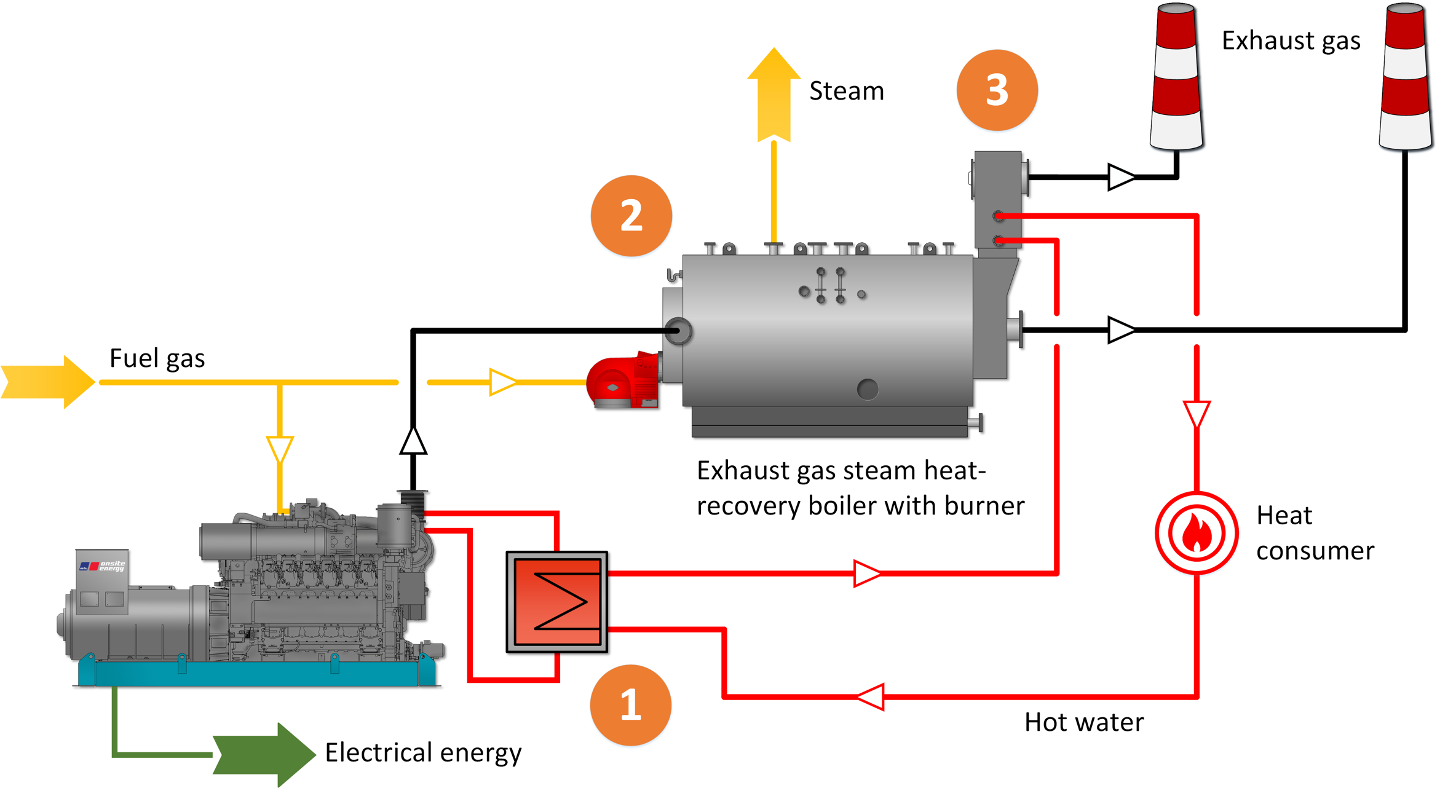

Solutions with steam recovery systems provide the Customer with two main products:

This is an optimal solution for the applications which require both steam and hot water. Our solutions allow delivering both saturated steam from 6 to 32 bars and superheated steam by using afterburning devices.

In this case the heat recovery system of gas reciprocating engine exhaust is executed with application of heat recovery steam generator (HRSG). With regard to the required steam pressure and temperature, necessity for supplementary firing and other specific requirements of each project, the heat recovery boilers can be both shell and water-tube type using various configurations of sub burner sections and multiple economizers.

In steam recovery solutions as a rule about 35-40% of heat energy generated by gas engine will be in the form of steam and 60-65% – in the form of hot water. In solutions with gas turbines applied as power generating prime mover the majority of the heat produced could be in the form of steam.

CHP based on gas reciprocating engine therefore has the following heat recovery steam system operating principle:

Engine exhaust gases at 400-450С (engine exhaust temperature) approach recovery sections of HRSG where boiler water heats up, become boiling and evaporation takes place. Steam recovery boiler may be physically executed as one -/ two - / three-sectional concept design (namely, 1 or 2 heat recovery sections and a section with a burner supplementary firing which design & nominal capacity is determined by calculation on a case-by-case basis). Steam recovery boiler may be supplied with feed water and system hot water heating economizers. Application of selection of economizers in steam recovery boiler provides for exhaust gases exit temperature reduction to 180-120С which contributes to the full use of engine exhausts heat capacity and achieving greater complete cycle efficiency.

In case of steam recovery boiler packaged with a system hot water heating economizer, system hot water flows first through engines cooling system where it is heated to 85C then to the hot water economizer where the water is further increased by exhaust gases latent heat up to 90-95С.

With respect to other details, the cycle arrangement is similar to that of solutions described in section “Heating-recycling systems with hot water production”.