Greenhouse CO2 fertilization solutions provide the Customer with three main products:

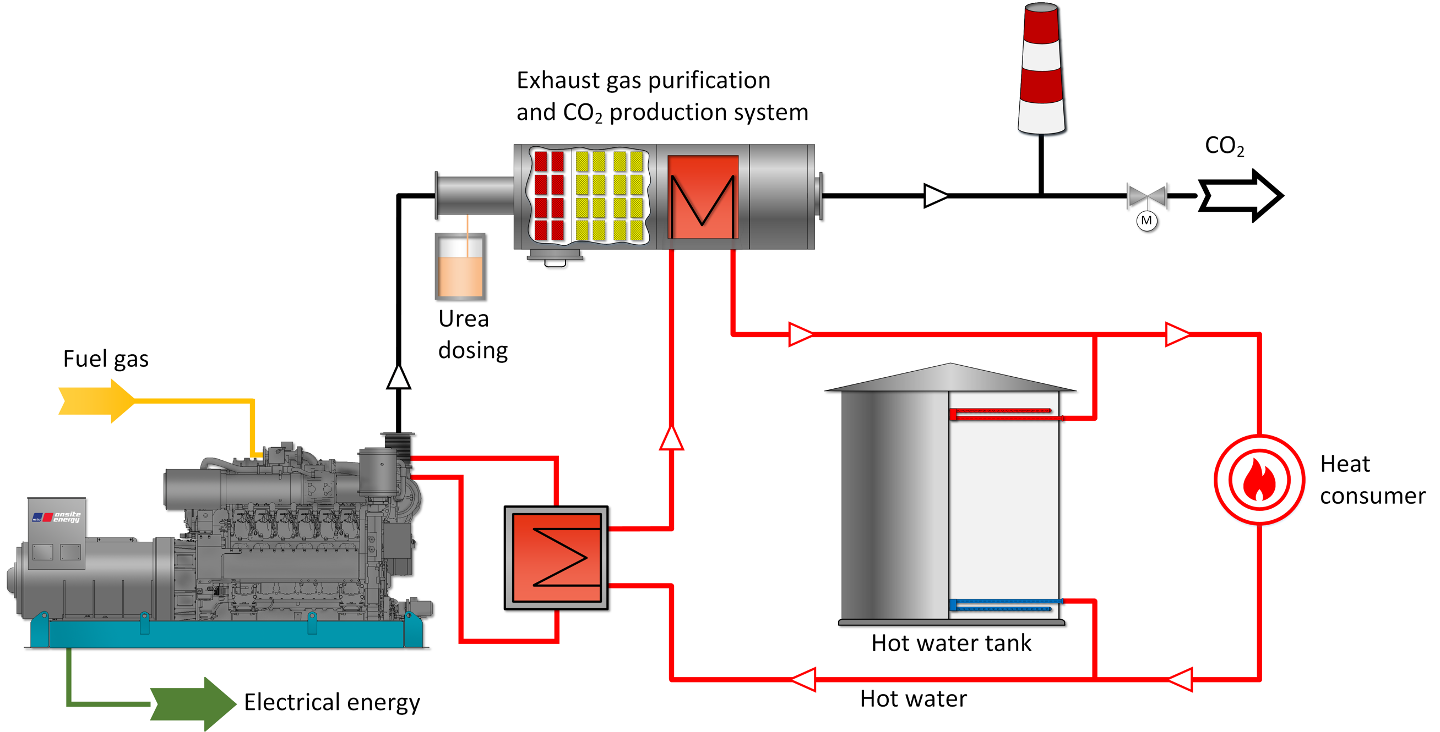

Greenhouse energy application is based on a gas-reciprocating engine exhaust gases treatment system which makes it possible to arrange simultaneous electricity, heat and CO2 generation for in-greenhouse use with maximum efficiency.

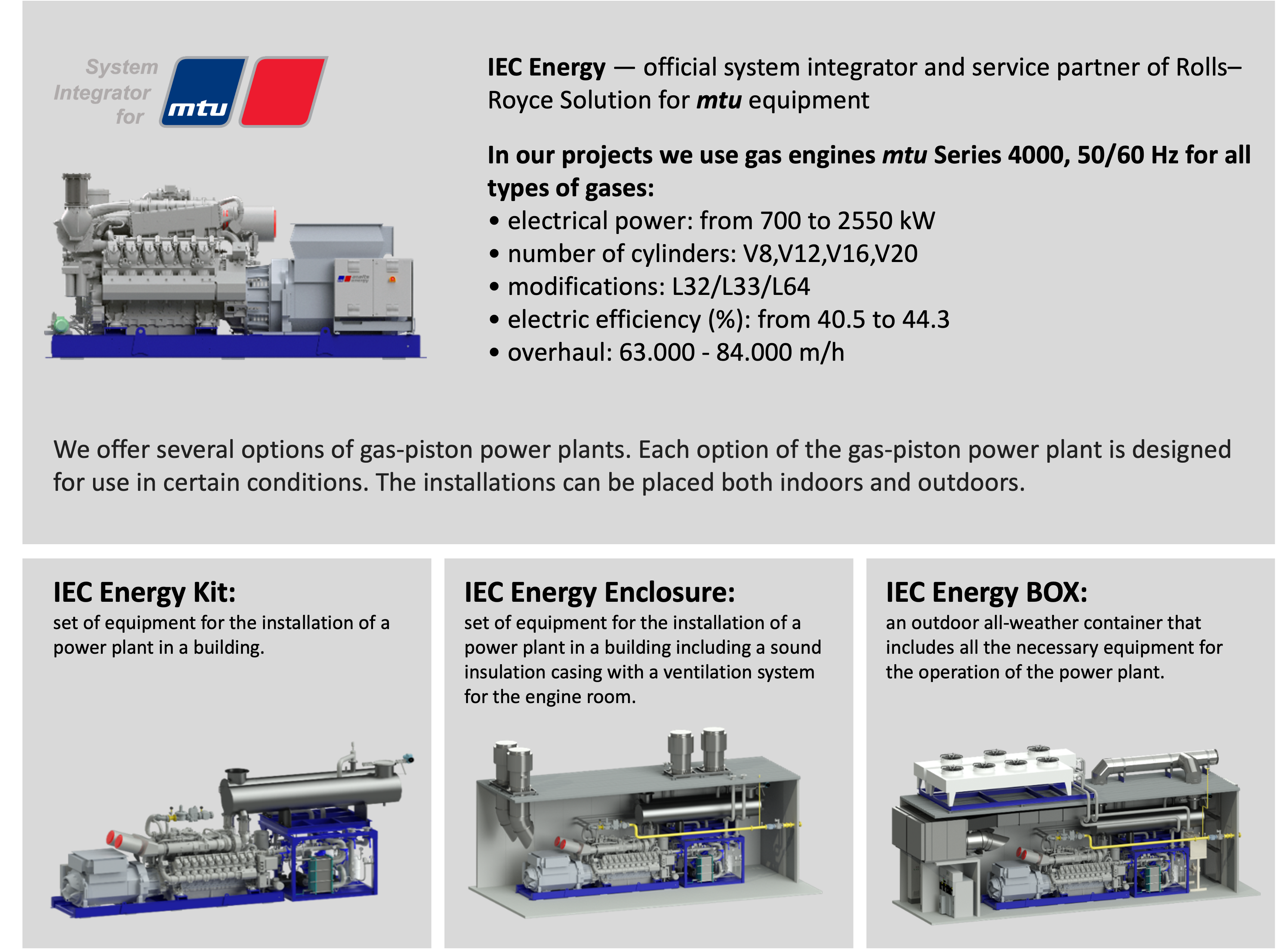

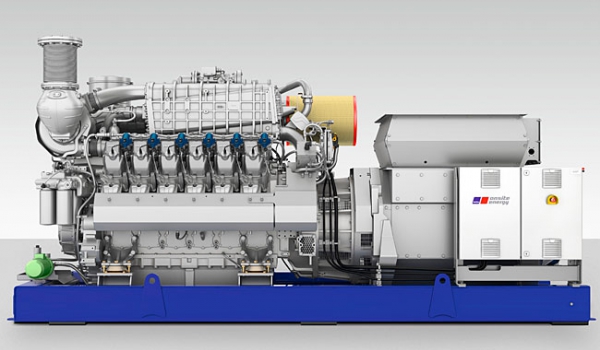

The main equipment in this solution is a cogeneration unit based on gas reciprocating engine. High electrical efficiency of gas reciprocating engine (in the range of 40-45% depending on engine capacity), comprehensive use of recovered heat for greenhouse heating combined with condensers applied for exhaust gases cooling to 50-600С make it possible to achieve the total plant efficiency of 92-95% allowing to maintain high overall equipment utilization and essentially lower electricity production cost comparing to the external grid rate.

Since vegetation yielding capacity depends to a great extent on CO2 concentration inside the greenhouse under roof, practically all modern semi-closed greenhouse facilities integrate the supply scheme of СО2 from hot water boilers allowing achieving СО2concentration in the greenhouse of about 500 ppm. The drawback of the boiler CO2 fertilization solution is impossibility to achieve the optimal СО2 concentration in the greenhouse (about 900- 1000 ppm) due to limited heat energy consumption by the greenhouse during summer time.

The installation of CHP plant is able to generate twice as much СО2 based on the same greenhouse heat consumption. It is possible due to the fact that 2 products from CHP are generated: electricity and by-product heat.

Assuming basic values of energy consumption by greenhouse complexes:

It can be calculated that energy complex based on cogeneration unit of 1 MW electric power capacity can supply 2…2.5 ha of a greenhouse facility by heat and CO2 demand and with coproduction of electricity sufficient for artificial lighting of 1 ha.

The use of exhaust gases treatment system makes it possible to have gases with the following concentration parameters:

NOx – reduction of concentration at urea dosing to <25 ppm

CO – finishing oxidation of CO concentration at catalyst agents to >99% (not more than 5 ppm)

С2Н4 (ethylene) – achieving concentration of <400 ppb

For the purpose of exhaust gases composition on-line monitoring and yield protection in case of the specified values exceeded, the treatment system is equipped with a stationary gas analyzer which performs continuous monitoring of exhaust concentrations and secure immediate shutdown of exhaust agent supply to the СО2 collector in case of permissible concentrations exceeded which makes it possible to guarantee safe greenhouse operation and personnel and vegetation healthy surroundings.